- Products

- Why Nudura

- Nudura Project Applications

- Training Academy

- Resources

- Company

How ICF Walls Are Less Expensive than CMU

By Cameron Ware

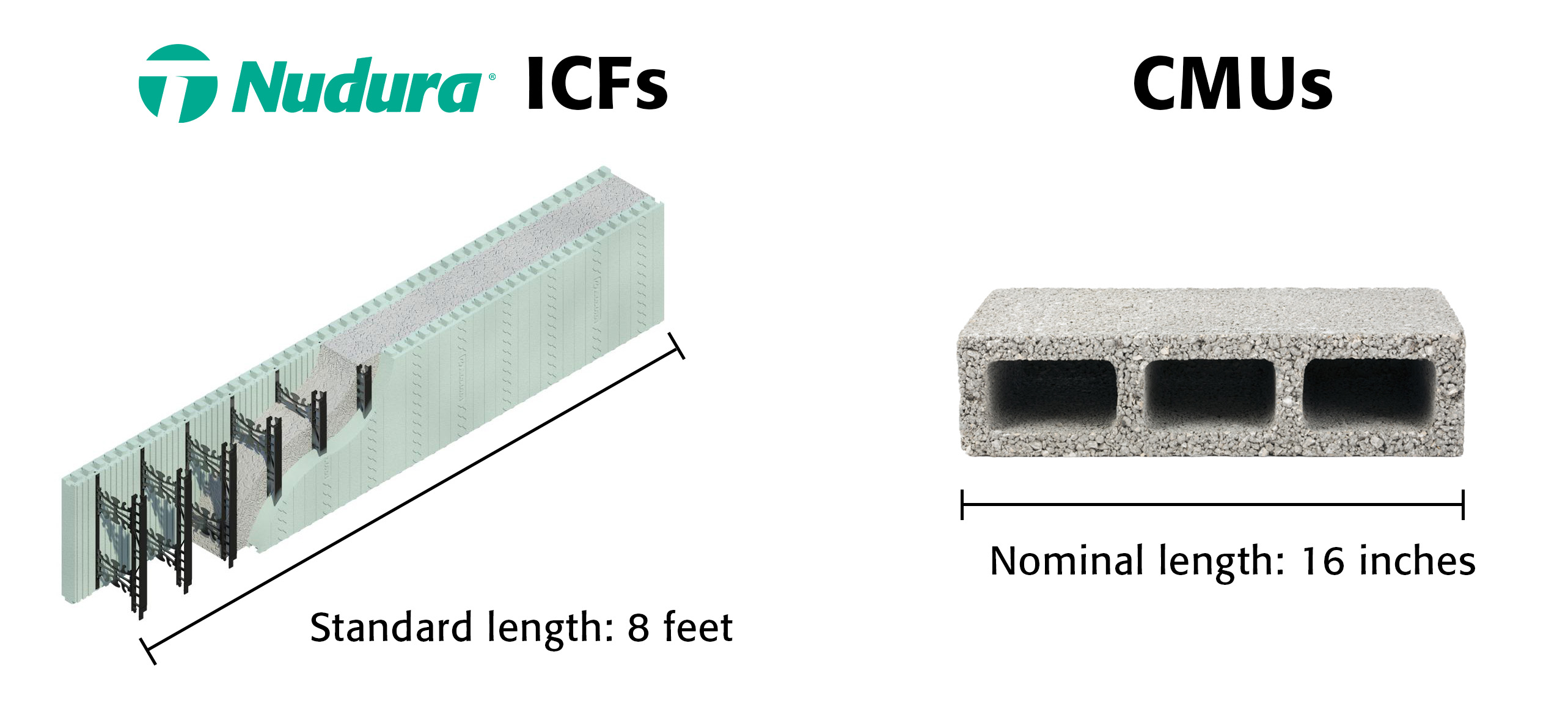

For building structural walls, concrete masonry units (CMU), also known as cinder block, concrete block, cement block, or foundation block, have enjoyed a significant share of the market over the last 50 years compared to other construction methods. However, the rise of insulated concrete form (ICF) technology has shown its superiority over CMUs in terms of performance, ease of installation, and ultimately cost.

ICFs offer greater design flexibility, install faster, and are stronger and more energy efficient than cinder blocks. Despite CMU’s head start in the industry, ICF continues to grow its market share. There tends to be a common misconception among architects, engineers, and general contractors that CMU is less expensive than ICF. You might be surprised to learn that the reverse is true. ICF construction is usually cheaper than cinder block—even before factoring in the cost savings from reduced energy bills.

Cost of Materials

How can we argue that ICF costs less than CMU? The assumption has been that a typical ICF wall will cost a few dollars more than the CMU. But the cost of cinder block construction is missing an important piece of the equation: steel.

ICF is more competitive right off the bat because it provides a reinforced monolithic concrete wall, often replacing steel as well as the CMU. But the CMU contractor or block mason rarely includes any steel in their bid. The rebar, embeds, and lintel steel that are necessary for cinder block wall construction are included in a separate scope of work. Since these extra items are not part of the CMU contractor’s bid, it appears on the surface that cinder block walls are more affordable. Once you consider all the necessary steel, the true cost of building a cinder block wall number is actually higher than what is typically cited.

Fur-Outs

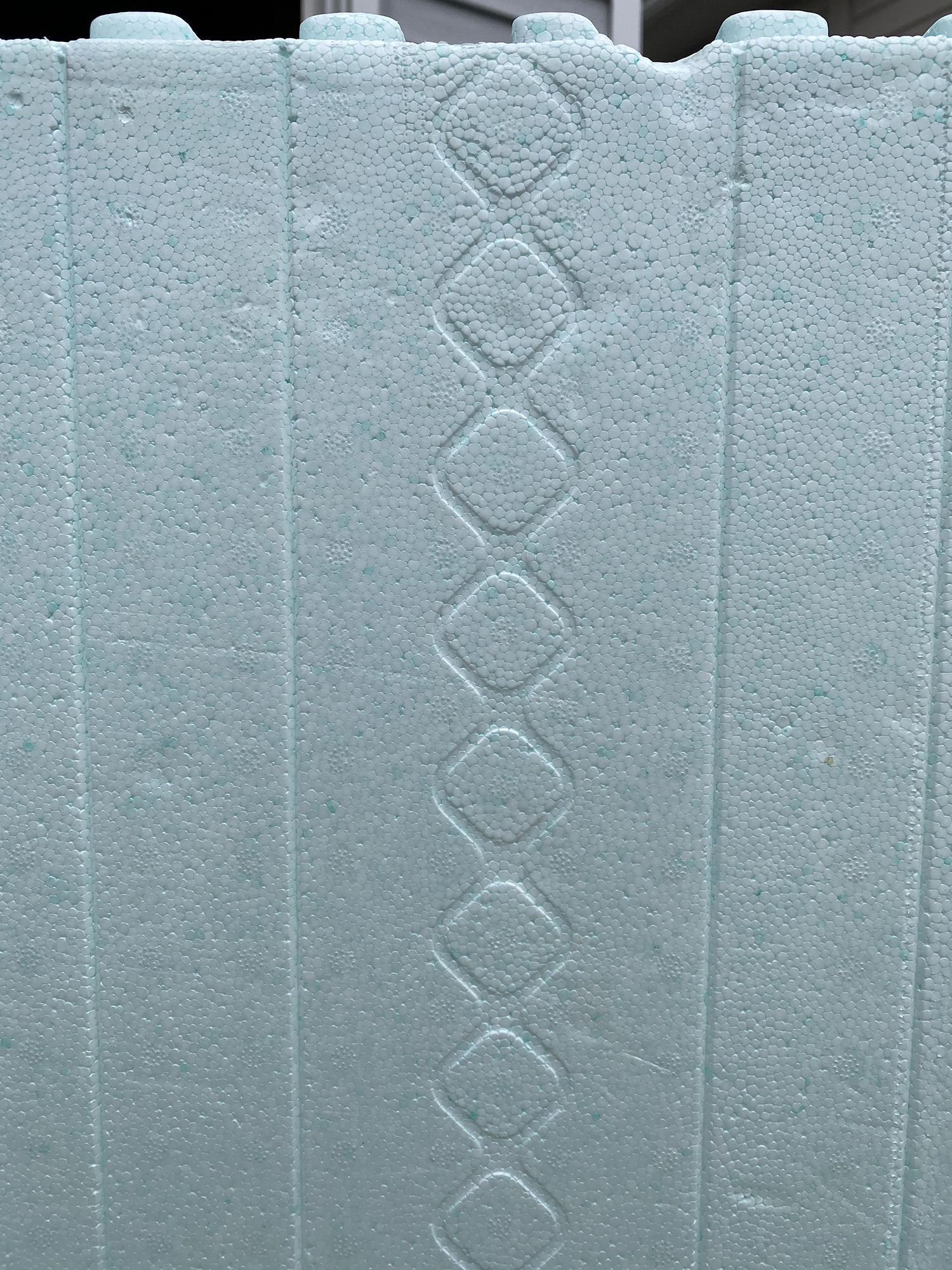

Check the drawings carefully for the finish system on the proposed wall assembly. For example, sheetrock can be attached to most ICF systems directly, while fur-out strips of some kind will be required to attach the sheetrock to the CMU. The cost of these fur-outs is usually in the framer’s number and is rarely included in the CMU bid. Fur-out work, depending on complexity, can run a few additional dollars per square foot if they are present. Even if the fur-out is as simple as furring channels for sheetrock– these numbers still allow CMU to bid low because the CMU contractor does not typically include fur-out costs in his bid. These additional costs are often eliminated by ICFs, which if you use Nudura, have built-in furring strips to streamline the installation of interior and exterior finishes. These are indicated by the diamond pattern embedded into the insulation.

Thermal Performance

When building with CMU, insulation costs may not be included in the block masons’ bids. However, a cinder block wall alone cannot compete with the continuous insulation of an ICF system. Therefore, efforts to improve the thermal performance of CMU to approach that of ICF will drive the cost up considerably. The placement of perlite or foam inside each CMU cell may bring the wall up to code, but it does not significantly improve the thermal performance of the assembly. The average R-value does not mean much if the inside and outside surfaces of the wall are connected with a conductor—namely concrete. Because of this, engineers would generally recommend adding a panel of foam insulation inside the air gap between the cinder blocks and the exterior cladding.

Should the engineer wish to replicate the ICF thermal performance, it is estimated that approximately five inches of continuous foam insulation would need to be installed with the CMU wall system, which would be costly.

These numbers do not take into account the financial savings for the owner after construction is complete. Due to the energy efficiency of ICF construction, owners see substantially reduced operational costs due to the decreased load on their HVAC systems.

Strength

The strength and weight of monolithic concrete, as is present with a fully cured insulated concrete form wall, is approximately twice that of cinder blocks. So if an architect wants a CMU wall to have the strength of an ICF wall, they may add perimeter steel columns to make the wall more durable and support the roof trusses. A good approximation or rule of thumb for the installed cost of steel is $3.5 per pound. Therefore, if a 10-foot column weighs 20 lbs/ft, it will cost about $700 in labor and material to install. Since these columns are not usually required for an ICF wall, the ICF wins out on structural integrity and price again.

Speed

Many general contractors are concerned about the speed of construction and the impact on other trades. With the light-weight nature of ICFs, they can be more easily moved around the jobsite compared to cinder blocks which can be labor-intensive. Depending on the skill and experience of your ICF crew, installation of insulated concrete forms is substantially faster than CMU. Time is money in construction, so a faster turnaround time means that contractors can more quickly move on to the next job and the owner can open their building to occupants sooner to recoup their investment.

Trades

Other trades, such as electricians and plumbers, may be hesitant to adopt ICF construction for fear of how their scope of work will be impacted by the seemingly new wall system. Once they understand the process, which has a minimal learning curve, they’ll quickly see that ICF is easier to work with than CMU. For example, penetrations for plumbing, HVAC and electrical lines can be made before or after the concrete is poured by simply cutting into the foam with a hot knife, electric chainsaw, or reciprocating saw.

Ultimately, when you compare all the factors that go into building structural walls, insulated concrete forms are faster to install, more energy efficient, stronger and less expensive compared to CMU and cinder blocks.

CONTACT US

We’re committed to supporting homeowners and design professionals who are interested in or use our products. We’re always happy to help and provide more information.